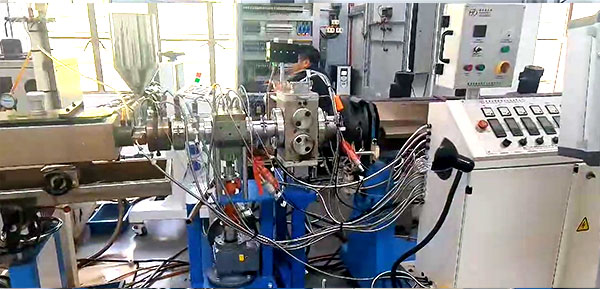

Melt pump and screen changer for PA12 nylon pipe extrusion production line

In PA12 nylon pipe extrusion production lines, the melt pump and screen changer form a core equipment combination that enhances production stability, product quality, and efficiency. Their synergistic operation achieves dual objectives of process optimization and cost control.

I. Melt Pump: Stable Delivery and Precise Metering

Core Functions

Through a precision gear meshing structure, the melt pump ensures stable delivery and high-precision metering of molten PA12 under high-temperature, high-pressure conditions. Its pump chamber design guarantees flow rate accuracy within ±1%, enabling precise control of pipe wall thickness. This prevents wall thickness deviations caused by feed fluctuations, significantly improving product yield rates.

Technical Advantages

Pressure Fluctuation Control: Eliminates extruder pressure variations, maintaining melt pressure fluctuations within ±1% to guarantee dimensional stability. For instance, in biaxially oriented polypropylene (BOPP) film production, the melt pump reduces film thickness deviation from 5% to below 1%. This principle similarly applies to high-precision PA12 pipe manufacturing.

Optimized Plasticization and Homogenization: Promotes thorough mixing and plasticization of materials within the extruder, enhancing pipe performance uniformity. As a highly crystalline material, PA12 is sensitive to melt temperature and shear rate. The melt pump reduces performance defects caused by localized overheating or insufficient shear.

Production Efficiency Enhancement: Enables extruders to operate at lower pressures, reducing mechanical energy conversion to heat. Simultaneously, precise temperature control decreases heating power requirements, resulting in overall energy savings of 30%-50%.

II. Screen Changer: Impurity Filtration and Continuous Production

Core Functionality

The screen changer intercepts unplasticized particles, foreign matter, and transport contaminants in PA12 feedstock via its filter screens, preventing these from entering the mold and causing surface defects, internal voids, or cracks in the tubing. Its rapid screen-changing capability enables non-stop operation, ensuring production continuity.

Technical Advantages

High-Precision Filtration: Select mesh fineness based on product grade requirements (e.g., 40-60 mesh for rigid pipes, 150-200 mesh for medical IV tubing) to ensure PA12 pipe purity. For instance, 100-150 mesh filters in food-grade packaging production intercept impurities >150μm, safeguarding product safety.

Non-Stop Screen Changes: Dual-column, dual-flow channel design enables simultaneous operation and replacement of screens, completing changes within 30 seconds. This eliminates downtime losses from traditional manual screen changes, boosting annual production capacity by 10%-15%.

Extended Mold Lifespan: Reduces wear and clogging of molds caused by impurities, minimizes product quality fluctuations due to mold damage, and prolongs equipment service life.

III. Synergistic Effects: Dual Enhancement of Process Optimization and Cost Control

Quality Synergy

The combination of stable melt pump delivery and high-precision screen changer filtration significantly improves the surface finish and mechanical properties of PA12 pipes. For example, during PVC profile production, the screen changer reduces “fish eyes” in the material while the melt pump enhances plasticization. This synergy lowers surface defect rates by 30%.

Efficiency Synergy

The melt pump reduces extruder pressure fluctuations, while the screen changer enables non-stop screen changes. Together, they minimize production downtime and increase equipment utilization.

Cost Synergy

The melt pump reduces material waste (e.g., 20% reduction in glass-fiber-reinforced PA12 production), and the screen changer extends mold lifespan. Their combined effect lowers overall production costs.

In PA12 nylon pipe extrusion production lines, the melt pump and screen changer establish a quality control system from raw materials to finished products through four core functions: stable conveying, precise metering, impurity filtration, and continuous production. Their technical advantages not only enhance dimensional accuracy and surface quality in high-end pipes but also deliver long-term economic benefits through energy savings, reduced consumption, and efficiency optimization. For PA12 pipe manufacturers pursuing high quality, high efficiency, and low costs, the combination of melt pumps and screen changers is an essential choice for modern production lines.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071