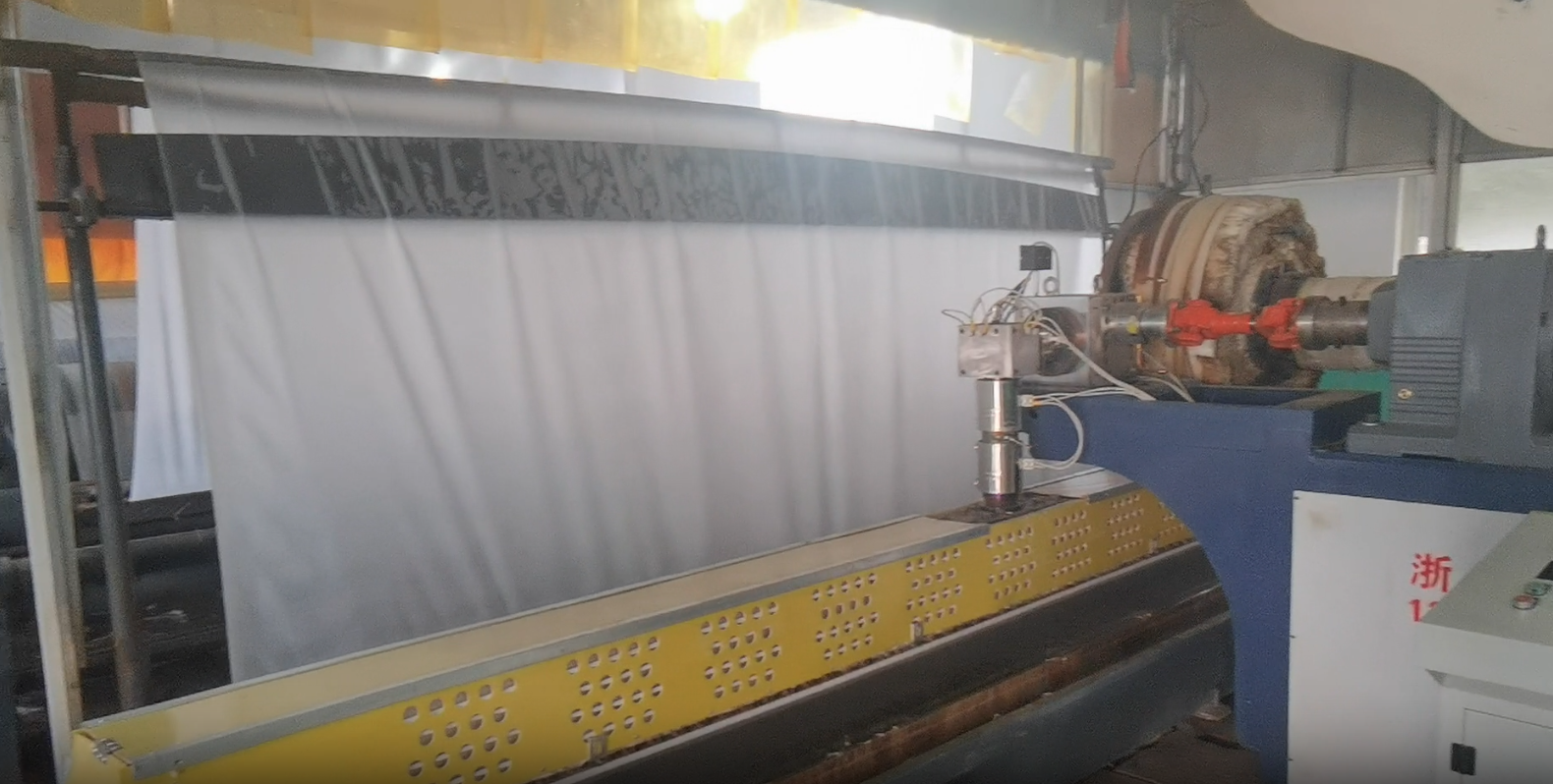

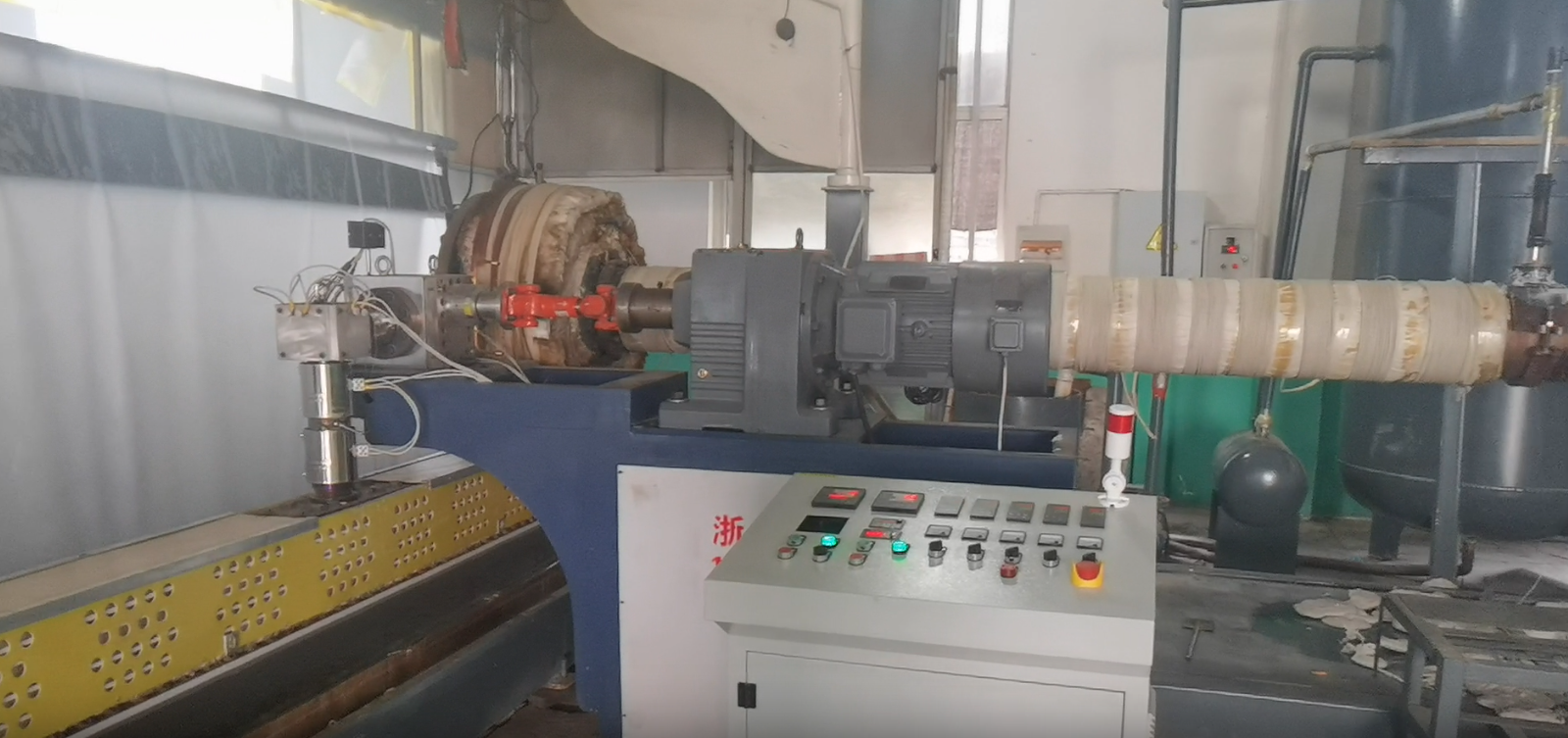

Melt pump for PP woven bag production line

Melt pumps hold significant application value in woven bag extrusion production lines. Their core functions include stabilizing melt pressure and flow rate, enhancing product quality, reducing energy consumption, and extending equipment lifespan. Specific analysis follows:

I. Stabilizing Pressure and Flow to Ensure Production Continuity

Woven bag production typically employs thermoplastic materials like polypropylene (PP). The extrusion process is susceptible to factors such as fluctuations in raw material viscosity and screw speed pulsations, leading to unstable melt pressure. Melt pumps utilize precision gear meshing to form a sealed cavity for melt conveyance, controlling outlet pressure fluctuations within ±1% (compared to ±5%-10% for conventional extruders). This completely eliminates pressure fluctuations' interference with extrusion stability. For instance, in biaxially oriented polypropylene (BOPP) film production, melt pumps reduce film thickness deviation from 5% to below 1%, significantly enhancing product uniformity.

II. Enhancing Product Quality to Meet High-Precision Demands

Key properties of woven bags—such as tensile strength and puncture resistance—are closely tied to melt homogeneity. During conveyance, the melt pump achieves shear and mixing of the melt through gear rotation, homogenizing the melt and reducing pulsation. This enables dimensional accuracy of extruded products to reach the micron level. For instance, in medical catheter production, lines equipped with melt pumps can control dimensional tolerances within extremely narrow ranges, meeting the stringent requirements of high-end products. For woven bags, the melt pump reduces flat yarn thickness deviation, enhancing the consistency of bag strength.

III. Reduced Energy Consumption and Low-Temperature Extrusion

Traditional extruders require high pressure to build melt pressure, resulting in high energy consumption. Melt pumps transfer the pressure-building function to the pump body, allowing extruders to operate at low pressure and temperature. This reduces mechanical energy conversion into heat and heating power consumption. Data shows that when combined with twin-screw extruders, melt pumps can reduce energy consumption by approximately 25% per kilogram of processed material. For woven bag production lines, this translates to significantly reduced electricity consumption and lower production costs at equivalent output levels.

IV. Extending Equipment Lifespan and Reducing Maintenance Costs

By stabilizing melt delivery, melt pumps reduce stress on extruder screws and barrels, slowing wear rates. For instance, after implementing melt pumps, one enterprise saw screw lifespan increase by over 30%, gearbox thrust bearing loads decrease by 20%, and maintenance intervals extend from monthly to quarterly. For woven bag production lines, enhanced equipment stability minimizes downtime for repairs, boosting overall production efficiency.

V. Adapting to Recycled Material Processing, Enhancing Environmental Benefits

Recycled polypropylene (rPP) is commonly used in woven bag production to reduce costs, but its high viscosity fluctuations often cause extrusion instability. Melt pumps effectively homogenize viscosity variations in recycled materials, narrowing melt index fluctuations from ±15% to ±3%, enabling successful application of recycled plastics in food-contact packaging. A European recycling company achieved over 95% yield for recycled HDPE after adopting melt pumps, providing technical support for circular economy initiatives in the woven bag industry.

Melt pumps serve as critical equipment in woven bag extrusion production lines. Their advantages—stabilizing pressure, enhancing quality, reducing energy consumption, and extending service life—significantly boost corporate competitiveness. As the plastics processing industry advances toward higher precision and lower energy consumption, the adoption of melt pumps will become an inevitable choice for upgrading woven bag production.